Featured Laboratory

1. Smart Manufacturing and Digital Transformation Laboratory (COBOT) Smart Manufacturing and Digital Transformation Laboratory aims at the development of Cobot and AR shop floor application, such as computer vision aided defect inspection, AR visualization, AR training and AR remote repair and maintenance.

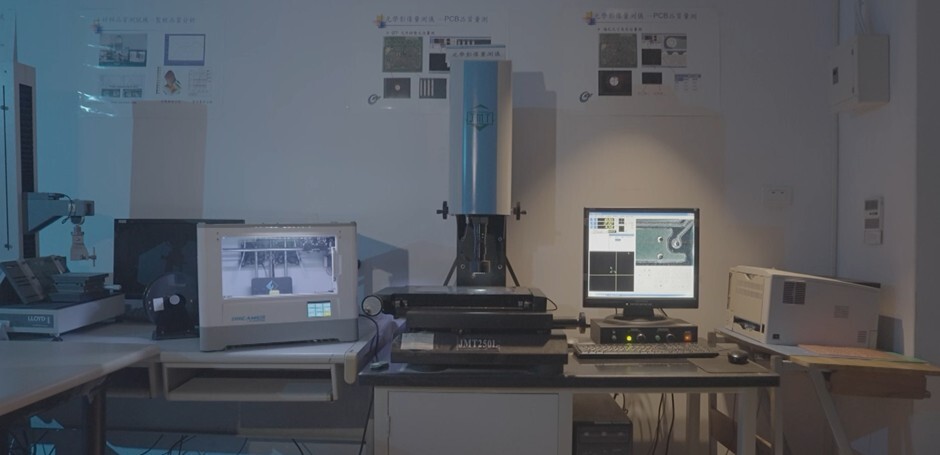

2. Quality Control Practice Classroom (optical Image measuring instrument & 3D printers) Quality Control Practice Classroom is designated for the following practices: (1) Modeling, 3D printing, measurement, and Gauge R&R analysis, (2) Use optical Image measuring instruments to measure critical features on circuit boards and IC components, and calculate Cp, Cpk, (3) Hands-on experiment with IoT sensor and IoT control panel for data collection, and conduct quality control, and (4) Establish a machine learning system to build models for identifying failure symptoms.

3. Lean Management Laboratory (for iPAS – Industry Professional Assessment System) Derived from the Toyota Production System (TPS), waste is removed at each step during the process. Through a series of integration, minimal raw materials, work-in-process, and finished goods inventory achieve high-yield products that meet customer needs. The Lean Management Laboratory assembly line is constructed with the concept of Karakuri.